Fun Info About What Is A 3-phase Current Breaker

Three Phase Voltage Calculations

Decoding the Mystery

1. Beyond the Single Lightbulb

Okay, so you've heard the term "3-phase current breaker" thrown around, maybe in a conversation about powering some heavy-duty equipment or even a factory. But what is it, really? Think of it like this: your typical home runs on single-phase power, like plugging a lamp into the wall. It's perfectly adequate for smaller appliances and lighting. But when you need to crank things up a notch, that's where three-phase power — and its trusty guardian, the 3-phase current breaker — comes into play.

Imagine a group of three people pushing a merry-go-round. Each person pushes at slightly different times, keeping the thing spinning smoothly and powerfully. That's kinda what three-phase power does. Instead of one wave of electricity (like in single-phase), you have three waves, offset from each other. This creates a more consistent and powerful flow of energy, ideal for big motors, industrial machinery, and other high-demand applications. This smooth power is what prevents flickering of lights in industrial facilities, and keeps machines running reliably.

Now, the 3-phase current breaker is essentially the safety net for this whole operation. Just like a circuit breaker in your home protects your wiring from overloads and short circuits, the 3-phase breaker does the same thing, but on a much larger scale. It's designed to trip (i.e., cut off the power) if it detects too much current flowing through the system. This prevents damage to equipment, fires, and other nasty consequences. You might picture it as the responsible adult in the room, always watching out for danger signs.

Think of a massive electric motor used in a manufacturing plant. These motors require a constant and large supply of electricity to operate correctly. If there were a short circuit in the motor or an overload, the wires would melt rapidly and potentially start a fire. The 3-phase breaker is the difference between a minor inconvenience and a major disaster. The breaker's response time is incredibly fast — fractions of a second. Faster than you can say "Oh, no!" The speed of the breaker is what saves equipment and lives.

Why Bother with 3-Phase Power in the First Place?

2. More Power, Less Fuss

So, why not just stick with single-phase power for everything? Well, it boils down to efficiency and capability. Three-phase power is simply more efficient at delivering large amounts of power. For the same amount of wire, a three-phase system can transmit significantly more power than a single-phase system. That means lower costs for infrastructure and less wasted energy. Which is good for both your wallet and the planet!

Another benefit is that three-phase motors are typically smaller, lighter, and more reliable than single-phase motors of the same horsepower. That's because the three-phase power creates a smoother, more consistent torque, which reduces wear and tear on the motor. Imagine trying to pedal a bicycle with only one leg — it's jerky and inefficient. That's single-phase power. Now imagine pedaling with both legs smoothly and evenly — that's three-phase power. Much better, right?

Consider the example of a hospital. Hospitals require consistent power, and a significant portion of their equipment such as MRI machines, air conditioning and large equipment require 3-phase power to operate. A hospital can't risk power failures, and three-phase power is more reliable than single-phase in the event of a partial failure because the system will still be able to distribute some power.

Ultimately, three-phase power allows for operation of higher power components. Consider the difference between your blender and a full-size cement mixer. The blender is able to operate from a wall-socket in your home, because it requires a small amount of power. The cement mixer, however, requires more power. Power that requires three-phase distribution.

How a 3-Phase Current Breaker Does Its Job

3. Sensing Trouble

Alright, let's peek under the hood and see how these breakers actually work. Inside a 3-phase breaker, you'll find a set of sensors and tripping mechanisms, one for each of the three phases. These sensors constantly monitor the current flowing through each phase. If the current exceeds a pre-set threshold, the tripping mechanism is activated. This mechanism is a very rapid release of energy that breaks the electrical connection, shutting off the power flow.

There are different types of tripping mechanisms, including thermal, magnetic, and electronic. Thermal breakers rely on the heat generated by the current to bend a bimetallic strip, which then triggers the trip. Magnetic breakers use an electromagnet to detect overcurrents. Electronic breakers use sophisticated circuitry to monitor the current and trip the breaker when necessary. The type of breaker used depends on the specific application and the level of protection required. Electronic breakers can be programmed for complex overload and short-circuit conditions, giving them the most reliable form of protection.

Many 3-phase breakers also have adjustable trip settings. This allows you to fine-tune the breaker to the specific needs of your equipment. For example, if you have a motor that experiences occasional brief overloads during startup, you can adjust the breaker to allow for these temporary spikes without tripping unnecessarily. It's like adjusting the sensitivity of a smoke detector — you want it to be sensitive enough to detect real fires, but not so sensitive that it goes off every time you burn toast.

One factor that contributes to the cost of 3-phase breakers is the complexity of the safety mechanisms. It's not just about shutting off the power, it's about doing it safely and reliably under all sorts of conditions. These breakers need to be able to withstand high fault currents (the amount of current that flows during a short circuit) and operate in harsh environments. That's why they're built to be tough and dependable.

How To Use Circuit Breaker

Spotting the Differences

4. Size, Shape, and Purpose

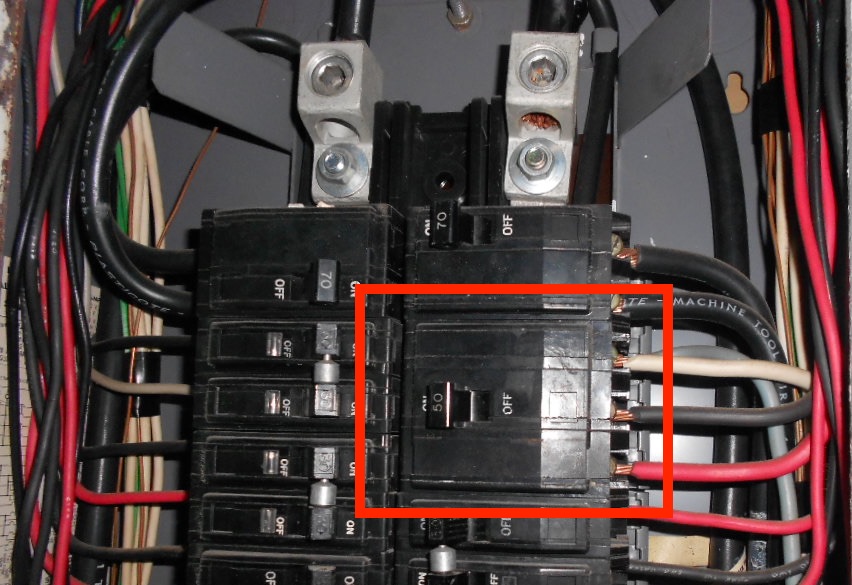

At first glance, a 3-phase breaker might look similar to a single-phase breaker. However, there are some key differences. The most obvious difference is the size. 3-phase breakers are typically larger and heavier than single-phase breakers, because they have to handle much more current and voltage. Think of it like comparing a garden hose to a fire hose — they both deliver water, but one is clearly designed for a much bigger job.

Another difference is the number of poles. A single-phase breaker typically has one or two poles, while a 3-phase breaker has three. Each pole corresponds to one of the phases of the power supply. You can think of each pole as an individual switch. To switch the power completely off in a 3-phase system, you have to break all three phases.

The voltage and current ratings are also different. Single-phase breakers are typically rated for 120V or 240V, while 3-phase breakers are rated for higher voltages, such as 208V, 480V, or even higher, depending on the application. The current ratings also tend to be much higher for 3-phase breakers, reflecting the higher power demands of the equipment they protect.

Finally, their applications are drastically different. Single-phase breakers can be found in homes, small businesses, and anywhere that does not need a high-power system. 3-phase breakers are used in industrial settings, commercial buildings, and other places where large amounts of power are needed. Now that you know what it is and why it is used, you can be more confident when speaking about electrical systems!

FAQ

5. Your Burning Questions, Answered

Still have some questions swirling around in your head? Here are a few frequently asked questions to clear things up:

Q: Can I use a single-phase breaker in a 3-phase system?

A: No, absolutely not! Using a single-phase breaker in a 3-phase system is a recipe for disaster. It won't provide adequate protection and could lead to serious damage or injury. It's like trying to put regular gasoline in a race car — it just won't work (and might blow up).

Q: How do I know if I need a 3-phase breaker?

A: If you're running heavy-duty equipment like large motors, welders, or industrial machinery, you likely need a 3-phase system and a corresponding 3-phase breaker. Also, if your building has three-phase power service, you will have a 3-phase panel with 3-phase breakers. Check the nameplate on your equipment or consult with a qualified electrician to be sure.

Q: Can I install a 3-phase breaker myself?

A: Unless you're a qualified electrician, it's strongly recommended that you don't attempt to install a 3-phase breaker yourself. Working with high-voltage electrical systems can be extremely dangerous and should only be done by trained professionals. This is one of those cases where DIY is not the way to go.

Q: What happens if my 3-phase breaker keeps tripping?

A: If your 3-phase breaker trips repeatedly, it indicates a problem in the electrical system. It could be an overload, a short circuit, or a faulty piece of equipment. It's important to investigate the cause of the tripping and address it promptly. Ignoring the problem could lead to more serious issues down the road. Contact an electrician to evaluate the system.